As defined by Carbon Trust, a carbon footprint is “the total set of greenhouse gas emissions caused directly and indirectly by an individual, event, organization, or product.”

Leading global enterprises have begun undergoing carbon footprint assessments to identify how much greenhouse gases (GHG) they are emitting and to better understand how their operations impact the environment. Therefore, taking carbon footprint assessment is the first step in reducing carbon emissions. It provides a baseline from which an organization can measure progress and helps identify areas throughout the production process and supply chain where a company can reduce emissions.

In June 2008, APP China commissioned the Camco Group, a third-party environmental assessment agency, to conduct a GHG assessment for the company’s main production activities.

APP China’s carbon footprint assessment included six of the company’s leading pulp and paper mills and two forestry plantations. Camco consultants conducted field research and data collection for these enterprises and the assessment covers “Plantation-Pulp-Paper” integration, raw materials, electricity consumption, gas consumption, back-up generators, company owned vehicles, waste disposal, business travel, commuting, etc.

Subsidiaries involved in the assessment:

6 pulp and paper mills:

Hainan Jinhai Pulp & Paper Co.,Ltd

Gold East Paper (Jiangsu) Co., Ltd

Gold Huasheng Paper (Suzhou Industrial Park) Co., Ltd

Gold Hongye Paper (Suzhou Industrial Park) Co., Ltd

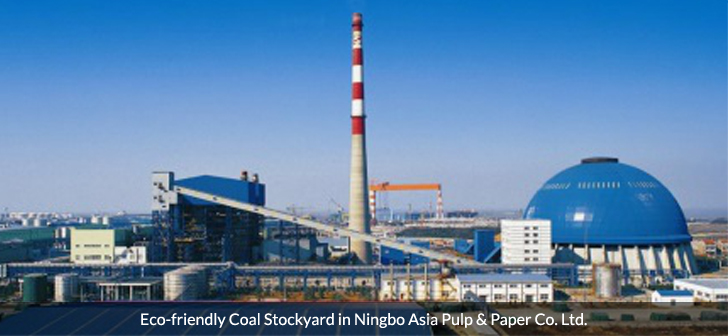

Ningbo Zhonghua Paper Co., Ltd

Ningbo Asia Pulp & Paper Co., Ltd

2 forestry plantations:

Jingui Forestry Co., Ltd

Hainan Jinhua Forestry Co.,Ltd

Coverage of Carbon Footprint Assessment:

| Product Carbon Footprint | |

| Products | Coverage |

| Forestry | Cultivation operations and saw mills, excluding nursery |

| Pulp | Saw mill operations, material input, pulp manufacturing process and finished goods |

| Paper | Paper manufacturing process from material input to the end of the manufacturing line and finished product delivery to warehouse |

| Corporate Carbon Footprint | |

| Operations | Coverage |

| All operational activities | Energy and vehicle use, commuting, business travel, deliveries, accommodation, waste disposal, etc. |

The total organizational footprint came to 6.944 million tons of CO2, and the total weighed production footprint was 1.49 ton CO2 per ton of paper, which are among the lowest in the pulp & paper industry.

In gathering and compiling the information, APP China was able to further clarify and identify areas for improvement in energy efficiency and cost reduction throughout its production and operational supply chain. The results will serve as a baseline for the company’s long-term strategy to reduce carbon emissions.

Recycled paper is made of materials which originate partially or totally from waste papers.

Using Pre-Consumer Waste and Post-Consumer Waste as raw materials in the production of recycled paper will generate less solid, air and water wastes, save large amounts of timber, reduce the use of chemicals and improve resource utilization, thus helping to protect environment and promote sustainability.

Comparing with virgin pulp and paper, 1 ton of recycled paper produced can help:

.png.jpg)

For 1 ton of waste paper recycled, it saves 17 trees, 30,000 litres of water and 3-4 MWH of electricity (which is enough to power an average 3-bedroom apartment for 1 year).

Ningbo Zhonghua and Ningbo Asia Pulp & Paper are among China's largest recycled industrial paper makers that use waste paper as raw materials, recycling more than 600,000 tons of waste paper respectively each year. By recycling waste paper, they save around 17 million trees from being cut down in a year.

Using recycled paper can bring many benefits to corporates, not only can it indicate the corporates' contribution to environment protection and its commitment to corporate social responsibility, improving corporate image, differentiating themselves from others using products that are not eco-friendly, enhancing brand image as well as competitiveness.

Recycling waste paper can help protect the environment. Go Green. Go Recycle!

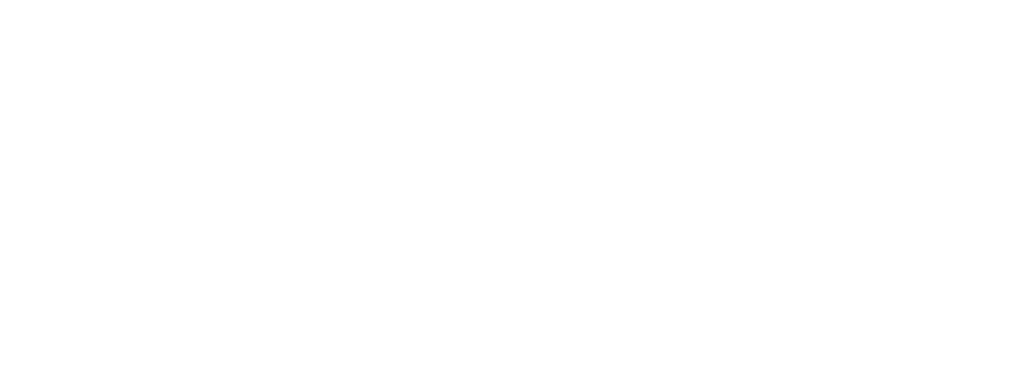

Wastewater treatment

- Can reduce water consumption per ton of paper / pulp.

- Can reduce wastewater discharge per ton of paper / pulp.

- Can reduce COD emissions per ton of paper / pulp.

Waste gases emission treatment

- Combustion system: Non-condensable gas produced during the cooking process of wood chips and odorous gas generated during the process of pulp making can be efficiently reduced through the alkali recovery combustion system.

- Desulphurisation facilities: Circulating fluidized bed and turbine generator can increase the desulphurisation rate effectively.

- Dust collection system: Electrostatic precipitator can collect suspended solids caused by the treatment boiler and lime kiln to reduce gas emission.

Resource utilization & fuel mix

By utilizing solid wastes generated in the pulp and paper making as biofuels can reduce coal utilization.